Linen, Wool, Silk: Why Natural Fibers Dominate Luxury Textiles

In large-scale interior architecture projects, textiles are not merely decorative elements applied a posteriori. They engage in dialogue with structure, correct acoustics, sculpt light, and confer upon a space its sensory identity. Noble fibers don’t impose themselves through their cost, but through their capacity to inhabit space enduringly.

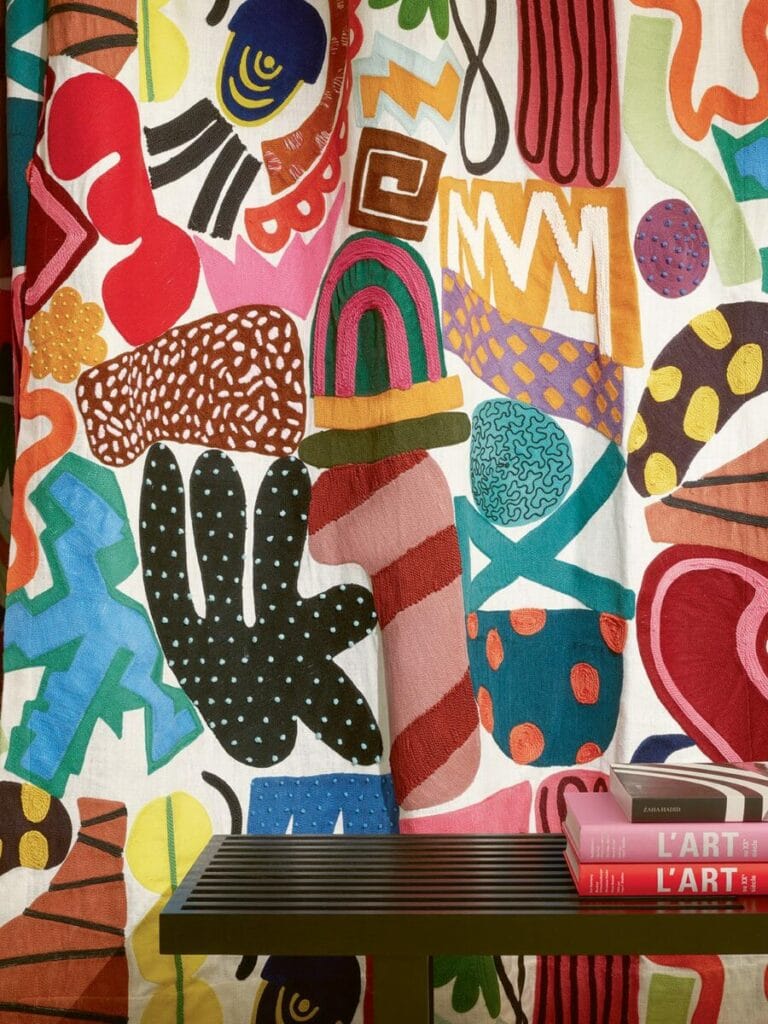

In the realm of high-end decoration, textile luxury no longer proclaims itself. It is felt. A hand gliding over mohair velvet, afternoon light revealing the depth of washed linen, the muffled silence brought by a heavy wool curtain: these are the true markers of excellence. Beyond trends and seasonal collections, three natural fibers have shaped the DNA of luxury upholstery textiles for centuries: linen, wool, and silk. Not as interchangeable materials, but as distinct languages, each carrying its own technical history, cultural geography, and aesthetic philosophy. Their presence in exceptional interiors is never incidental: it embodies a vision of time, use, and transmission.

The shift toward the long view: why noble fibers are making a comeback

For several decades, the upholstery textile industry prioritized technical performance: wear resistance measured in Martindale cycles, color fastness, ease of care. Synthetic fibers—polyester, acrylic, viscose—dominated the mass market and even certain high-end segments, promising standardized durability.

But over the past fifteen years, a reversal has occurred. The most discerning specifiers and clients now seek textiles capable of aging gracefully rather than resisting indefinitely without evolving. This quest for “long-term value” rehabilitates noble natural fibers, not through nostalgia, but because they offer sensory richness, aesthetic evolution over time, and a tactile relationship that synthetic materials cannot authentically replicate.

Linen develops a patina. Wool densifies. Silk captures light differently with the seasons. These properties, long perceived as commercial weaknesses, become the assets of redefined luxury: living, repairable, transmissible.

Linen: structural elegance and material intelligence

Perhaps better than any other fiber, linen embodies the contemporary evolution of luxury. Long confined to summer tablecloths and vacation wear, it now asserts itself as an architectural material in the most refined interiors. Why this shift? Because linen combines three rare qualities: visual lightness, technical strength, and tactile nobility.

Anatomy of a European fiber

Cultivated flax (Linum usitatissimum) is an annual plant that grows naturally in humid temperate climates. France, Belgium, and the Netherlands today concentrate nearly 80% of global production of superior quality textile linen—a major geographic asset in an era of supply chain relocation.

The linen fiber has a hollow structure that provides excellent thermoregulation: cool in summer, insulating in winter. Its mechanical strength exceeds that of cotton (particularly in wet tensile strength), making it especially suitable for upholstery textiles subject to structural constraints: heavy curtains, slipcovers, wall hangings.

Woven linen: from rustic canvas to sophisticated velvet

The technical evolution of woven linen has been spectacular over the past twenty years. High-end textile publishers have developed remarkably complex constructions: washed and stonewashed linen canvases inspired by denim, which provide immediate suppleness and a slightly crumpled appearance avoiding any rigid formalism; linen-wool blends combining linen’s visual freshness with wool’s depth and body, particularly prized for contemporary curtains; linen velvets achieved through jacquard weaving or bouclé yarn insertion, marrying linen’s lightness with velvet’s tactile richness; or metallic or silk-backed linen for use in wall coverings or prestige curtains, bringing depth and plays of light.

Linen in space: uses and performance

In interior decoration, linen excels in several registers. For curtains and sheers, filtered linen allows soft, diffused light through, creating soothing atmospheres. High ceilings particularly benefit from heavy linen curtains (300 to 450 g/m²) that fall elegantly without stiffness. In slipcovers and lightly used seating (reading chairs, headboards, decorative benches), linen withstands moderate use well but requires attentive care for high-traffic pieces. As wall hangings, linen brings noble texture and appreciable acoustic absorption capacity.

European linen: an environmental assessment to be nuanced

Linen benefits from a flattering ecological image, partly justified by its cultivation requiring little irrigation in northern Europe’s humid climates and an initial transformation that is essentially mechanical. Its rapid growth (one hundred days from seed to harvest) and compatibility with crop rotation make it indeed a virtuous agricultural plant. European supply chains also offer traceability that few other fibers can claim.

But this beautiful story becomes complicated downstream. The dyes and chemical finishes necessary to transform raw linen into luxury textile (bleaching, softening, stonewash) consume significant water and energy. More problematic still, a growing portion of European fibers travels to Asia to be spun and woven before returning to Western markets, thus canceling the carbon advantage of local production. In high-end products, GOTS or Oeko-Tex certifications and complete production chain verification remain the only guarantees of truly responsible linen.

Part 2/4

Wool: textile architecture and structural comfort

If linen captures light, wool sculpts space. A volumetric material par excellence, it brings physical presence, acoustic absorption, and tactile depth. In high-end interior architecture projects, wool is not merely a covering: it participates in the sensory construction of place.

Diversity of wools: from merino to mohair

Contrary to common belief, “wool” does not designate a single fiber but a family of animal fibers with very different properties. Merino wool, fine and soft, is used in high-end upholstery textiles for its silky hand and capacity to take deep dyes, with correct abrasion resistance making it suitable for cushions, throws, and small seating pieces. New Zealand and Australian wools, more rustic and thick, are generally reserved for high-end carpets and rugs where their excellent resilience guarantees longevity in high-traffic areas. Mohair, from the Angora goat, represents the aristocratic fiber par excellence: natural brilliance, exceptional softness, and superior mechanical strength make it one of the most sought-after fibers in luxury upholstery, particularly in velvet. Alpaca, a very soft, light, and insulating fiber, remains of still confidential use in Europe but is developing for high-end collections of throws and cushions.

Wool and mohair velvet: the technical summit of upholstery textiles

Wool velvets and especially mohair velvets represent absolute excellence in seating and upholstery textiles. Their manufacture requires specialized looms and rare expertise, today concentrated in Italy, Belgium, and France.

The principle of velvet relies on the insertion of looped yarns (bouclé velvet) or cut yarns (cut velvet) that create a dense, uniform surface. In the case of mohair, the natural brilliance of the fiber produces changing light effects depending on viewing angle—a characteristic sought by interior architects to energize spaces.

The finest upholstery textile houses offer mohair velvets with exceptional densities (up to 120,000 points/m²), capable of withstanding 50,000 to 100,000 Martindale cycles while maintaining their initial appearance. These textiles, far from being fragile, are among the most durable on the market—provided the weaving and construction are impeccable.

Wool in space: uses and acoustic performance

Wool occupies a structural place in high-end projects. Mohair velvets are designers’ privileged choice for contemporary seats and sofas, their resistance, comfort, and incomparable hand justifying their high cost. In hand-woven or tufted carpets, New Zealand wool remains the reference for exceptional pieces, combined with silk for brilliance or linen for texture. Thick wool fabrics (felts, wool drapes) are used in acoustic curtains and panels for their capacity to absorb sound reverberations, a major issue in high-ceilinged or glazed spaces. Finally, throws and decorative blankets in merino wool, alpaca, or wool-cashmere blends bring a touch of discreet and functional luxury.

Wool: a global supply chain with multiple faces

Wool presents a fascinating environmental paradox. On one hand, its exceptional durability makes it one of the most virtuous fibers in the long term: a mohair seat can span several decades, be restored, rewoven, thus extending its useful life well beyond any synthetic textile. Wool is an annually renewable fiber, biodegradable at end of life, and fits perfectly into a circular economy logic where repair takes precedence over replacement.

But this beautiful story confronts the reality of a globalized and unequal supply chain. The carbon footprint of sheep farming, particularly related to methane emissions and extensive land use, weighs heavily in the overall balance. Controversial practices like mulesing in Australia raise legitimate ethical questions. Intercontinental transport from New Zealand or Australia to Europe considerably increases the carbon footprint, while chemical treatments of raw wool (scouring, bleaching, moth protection) are not without environmental impact.

In authentic luxury, the difference lies precisely in these details: RWS (Responsible Wool Standard) certifications, wools from farms respecting animal welfare, vegetable or low-impact dyes. The most demanding publishers now document the complete origin of their wools and communicate openly about their supply chains, aware that transparency has become a component of contemporary luxury.

Silk: light, rarity, and measured use

Silk occupies a place apart in luxury upholstery textiles. It is not a structural material nor one of mechanical performance: it is a material of light. Its unique reflective power, capacity to reveal the most subtle chromatic nuances, and incomparable texture make it an exceptional textile, reserved for chosen and protected uses.

Anatomy of a precious thread

Silk is produced by the silkworm (Bombyx mori) which secretes a continuous thread that can reach 1,500 meters in length to form its cocoon. This thread, composed of fibroin coated with sericin, has a triangular cross-section that refracts light like a prism, hence silk’s characteristic luster.

In upholstery, several types of silk coexist. Raw silk, not stripped of its sericin, presents a more matte and rustic appearance, used for certain ethnic or contemporary textiles with a raw effect. Degummed silk, the most common in upholstery, is soft, brilliant, and suitable for deep dyeing. Wild or tussah silk, produced by non-domesticated worms, offers a more irregular thread, less smooth texture, and naturally beige or golden tones.

Silk velvet and jacquard fabrics: extreme sophistication

Silk velvet represents one of the technical summits of textiles. Its manufacture requires extremely precise looms and rigorous thread selection. The result: unequaled color depth and tactile softness.

Silk jacquard fabrics (damasks, lampas, brocades) perpetuate centuries-old European expertise. Lyon remains a world center for these ultra-specialized manufactures, where each piece requires weeks of setup and weaving. Houses like Prelle (Lyon), Tassinari & Chatel, or Rubelli (Venice) keep this tradition alive, particularly for heritage site restoration and exceptional projects.

Silk in space: reasoned and strategic uses

Unlike linen or wool, silk is not a material for intensive daily use. Its relative fragility to abrasion, UV, and humidity requires thoughtful and protected use.

In wall hangings, silk mounted on rigid backing escapes mechanical constraints and reveals all its beauty. Grand private mansions and luxury hotels still use this type of decor in reception rooms, where silk deploys its sophistication without suffering wear. For lined curtains and valances, silk as the face fabric, backed with protective material (cotton, linen), brings depth and luminosity without exposure to friction. Cushions and decorative elements welcome silk in precious details: trimmings, piping, cushion faces on lightly used sofas. Finally, headboards and upholstered panels, vertical areas with little direct contact, allow silk to fully express itself.

Silk: ancient luxury, modern questions

Silk carries within itself a fundamental contradiction of contemporary luxury. A natural and biodegradable fiber, it requires little cultivated land (mulberry trees suffice) and produces low volume for very high added value. When used in protected conditions, its durability can be exceptional, spanning centuries as evidenced by historical lampas restored by Lyon manufactures.

But this ancient elegance confronts the realities of production concentrated in Asia, primarily China and India, involving long-distance transport and sometimes opaque working conditions in industrial spinning mills. The very process of unwinding cocoons involves the death of chrysalises, raising an ethical debate that some manufacturers attempt to circumvent with “peace silk” (where butterflies emerge naturally, producing lesser quality fiber). Chemical dyes, often unregulated in mass production, also raise questions.

European high-end supply chains, notably in Lyon and Como, favor certified silks and controlled dyes, but remain a minority facing global production dominated by other logics. In true luxury, silk thus asserts itself as an assumed choice: conscious of its impact, selective in its sources, and always justified by use that honors the rarity of the material.

Technical comparison: choosing the right fiber by use

Luxury does not reside in the systematic use of the most expensive material, but in the rightness of choice according to use, exposure, and expected lifespan.

Comparative performance

In terms of abrasion resistance measured in Martindale cycles, mohair velvets rank well ahead with 50,000 to 100,000 cycles, followed by thick tightly woven linen reaching 15,000 to 25,000 cycles, while silk, with only 5,000 to 10,000 cycles, requires protected use. For light resistance (scale 1 to 8), wool and mohair excel with a rating of 6 to 7 guaranteeing very good color fastness, linen maintains between 5 and 6 with possible natural bleaching, whereas silk, sensitive to UV with a rating of 3 to 4, requires linings or specific protections.

In acoustic absorption, thick wool (drapes, felts) proves excellent, heavy woven linen offers good performance, while silk, fine and smooth, remains ineffective on this front. In thermoregulation finally, linen and wool both distinguish themselves through their excellence, the former bringing coolness in summer and moderate insulation in winter, the latter guaranteeing optimal thermal insulation, silk positioning itself correctly with its insulating lightness.

Prescription guide by use

For seats with intensive daily use in family living rooms or dining rooms, one favors mohair velvets, thick wool-linen blends, or certain high-density washed linens. Curtains in full light call for natural linen or resistant dyes, linen-cotton blends, or light lined wool. Bedrooms and intimate spaces readily welcome soft linen, wool or silk velvets in decorative elements. For wall coverings, one opts for textured linen, mounted silk hangings in protected areas, or felted wool for its acoustic qualities. Finally, carpets are ideally constructed in pure New Zealand wool or silk blend for brilliance, or wool-linen combination for a contemporary rendering.

High-end supply chains: reference manufacturers and publishers

In the world of luxury upholstery textiles, quality is not decreed: it is built through complete mastery of the production chain. A few major players embody this excellence.

Masters of linen

Marc Alexander, based in Milan, offers collections of sophisticated linens often blended (linen-silk, linen-wool) with impeccable finishes and intensive use of stonewash and subtle dyes. Élitis, a Toulouse manufacture, develops a contemporary approach to linen with bold blends, innovative textures, and strong colorimetric identity. Libeco in Belgium, Belgian linen specialist, cultivates a sustainable and traceable approach with refined collections designed for contemporary architecture.

Wool and mohair specialists

Rubelli in Venice remains the absolute reference for silk and mohair velvets, offering historical and contemporary collections of exceptional weaving quality. Lelièvre in Paris perpetuates a strong French manufacturing tradition with its wool and mohair velvets and jacquard fabrics. Houles, also Parisian, combines passementerie and upholstery fabrics with dense mohair velvets from preserved expertise. Kvadrat in Denmark develops a Nordic approach to textiles with technical wools for architecture, minimalist design, and excellent acoustic performance. Donghia in the United States offers contemporary mohairs in international collections with strong presence in luxury hospitality projects.

Guardians of silk

Prelle, Lyon manufacture founded in 1752, remains the undisputed specialist in silk lampas and damasks, supplier to national palaces and heritage projects. Tassinari & Chatel, also from Lyon, perpetuates the art of figured silk fabrics with historical reconstructions and exceptional contemporary collections. Rubelli in Venice cultivates Italian textile expertise with its silk velvets and Venetian damasks. Jim Thompson in Thailand offers high-end Asian silks, blending traditional and contemporary patterns with strong chromatic identity.

Care and durability: keeping noble fibers alive

One of the paradoxes of luxury textiles is that their exceptional durability only reveals itself if care is mastered. Noble fibers require regular but non-constraining attention.

Linen is maintained by regular vacuuming and dry cleaning for mounted pieces, with machine washing possible for certain unstructured linens like removable covers. Prolonged direct sun exposure causing progressive bleaching must be avoided, and cushion rotation practiced for uniform use. Reweaving remains possible for small tears, and cover replacement is easily done.

Wool and mohair require gentle vacuuming with soft brush, professional dry cleaning every two to three years for seats, and specialized shampooing for carpets. Regular brushing in the direction of the pile revives appearance, while natural moth protection (cedar or lavender sachets) is essential. Mohair velvets, extremely resistant, can have minor wear repaired by professional reweaving.

Silk demands delicate dusting and dry cleaning exclusively entrusted to professionals specialized in antique textiles. Any direct UV exposure must be avoided, systematic linings protect curtains, and cushion rotation preserves uniformity. Repair, complex and costly, remains reserved for exceptional pieces like historical lampas or brocades.

And what about viscose? The paradox of an “natural” ephemeral fiber

It would be dishonest to conclude this exploration of luxury textiles without addressing viscose, this fiber omnipresent in contemporary high-end collections but which raises a fundamental question: can one be both “natural” and disposable?

The ambiguity of a fiber between two worlds

Viscose belongs to the family of artificial cellulosic fibers. Made from plant cellulose (generally wood: beech, eucalyptus, bamboo) but chemically transformed to become spinnable, it is technically of natural origin but synthetic manufacture. This semantic ambiguity is at the heart of the problem: viscose is often presented as “natural” or “ecological,” when its manufacture requires heavy chemical processes and its durability is well inferior to true natural fibers.

Why it dominates in luxury

Over the past decade, viscose has massively established itself in high-end collections for three technical reasons: its exceptional fluidity and drape effect (blended with linen at 30-50%, it corrects its natural stiffness), its capacity to absorb dyes remarkably producing deep and saturated colors, and finally its controlled cost allowing maintenance of high aesthetic level at reasonable price. Publishers like Dedar, Élitis or Designers Guild massively use these linen-viscose blends for their collections of sheers and lightweight fabrics.

The problem: it doesn’t last

But here’s the paradox: viscose ages poorly. Unlike linen which develops patina, wool which densifies, or silk which retains its luster when protected, viscose presents low mechanical resistance (it wears quickly in intensive use), extreme sensitivity to humidity (50% resistance loss when wet), progressive chemical degradation (yellowing, loss of suppleness, fragilization), and major care difficulty (delicate dry cleaning only). Result: a magnificent textile at purchase but which, five to ten years later, shows signs of irreversible wear, where well-maintained linen, wool or silk can span several decades.

Ecological impact: when “natural” doesn’t rhyme with durable

The traditional viscose manufacturing process relies on carbon disulfide, a highly toxic product responsible for serious pollution in producing countries (China, India, Indonesia). Growing cellulose demand creates pressure on forests, despite FSC or PEFC certifications. The process consumes significant water quantities and generates effluents difficult to treat.

But the real ecological problem lies in its short lifespan: a fiber that requires so many resources and chemistry to be produced, but degrades in five to ten years, poses a fundamental question of coherence. “Improved” variants like Tencel or Lyocell reduce chemical impact but resolve neither deforestation nor limited durability. In authentic luxury defined by an object’s capacity to span time, viscose appears as a contradiction: it borrows the vocabulary of natural without assuming the philosophy of the long view.

A place to define

Viscose finds its legitimacy in certain specific uses: lightweight sheers, curtain linings, technical blends to improve linen drape. But it should never be presented as an ecological alternative to noble natural fibers, nor used for structural pieces meant to last decades. True luxury imposes honesty: if viscose is chosen, it’s for its specific technical qualities, in knowledge of its limits, and not as an economic substitute masked behind misleading “natural” discourse.

Conclusion: material as culture of the long view

Linen, wool, and silk dominate luxury upholstery textiles because they respond to a demanding definition of high-end: a material that tells a story, ages with dignity, can be repaired, and spans generations.

In a context where the global textile industry struggles to reconcile volume and durability, noble fibers remind us that another model exists: that of controlled production, assumed traceability, and transmissible value. Choosing a mohair velvet woven in Como rather than cheap synthetic is not an ostentatious gesture. It’s an act that engages a vision of time, use, and transmission.

Interior architects and decorators who specify these materials don’t seek to impress: they build spaces capable of lasting, evolving, telling stories. True luxury is not measured by price per square meter, but by a textile’s capacity to inhabit a place for thirty years without losing its aesthetic relevance or technical quality.

In contemporary luxury, material is not a covering. It is a language, a culture, an ethic of the long view. Noble fibers are its living grammar.

Digital entrepreneur and craft artisan.

My work bridges craftsmanship, design history and contemporary creation, shaping a personal vision of luxury interior design.

Since 2012, I have been based in my workshop on the shores of Lake Annecy, creating bespoke interiors for architects, decorators and private clients.