The Truth About Upholstery Foams: What’s Really Inside Your Chairs and Sofas

Info, expert advice and opinions on different types of foam

Demand for custom sofas has been growing at the workshop lately, and the question of ecology systematically comes up in conversations with my clients. “What natural options do you have?”, “Is it possible without petroleum?”, “And latex, is that good?”. Legitimate questions that deserve honest answers.

But beyond our clients, it’s also us, furniture professionals, who are concerned by these questions. As an upholstery artisan, I have my nose in these foams all day long. I cut them, handle them, breathe their dust. When a foam gives off strange odors, it’s my workshop that reeks for weeks. When it emits VOCs, it’s my lungs that suffer. This toxicity question isn’t theoretical for me – it’s a workplace health issue.

So I went out to get a complete overview of the foams that are actually available to us for upholstering a custom sofa today. From the lowest to the highest quality, including so-called “ecological” alternatives. Guess what? The more ecological it is, the more expensive it gets. But more importantly, I discovered that the “all natural” promise in sofa upholstery often amounts to marketing fantasy.

But by the way, what is foam?

Before diving into the details, a basic reminder: foam is air trapped in plastic material. Period. All the magic (and all the chemistry) lies in the way we create and stabilize these millions of tiny bubbles.

The three main foam families

Polyether foam

Polyether foam is the most basic, the lowest quality and the cheapest. It has a closed-cell structure (the bubbles don’t communicate with each other), which makes it poorly breathable and not very resilient. It “dies” quickly – meaning it loses its ability to recover its shape. You find it in discount sofas, decorative cushions, and packaging. Density generally between 16 and 30 kg/m³.

Polyurethane foam

Polyurethane foam is more elaborate. It exists in standard version and HR version (High Resilience).

The difference? The size and structure of the cells. HR has larger, open cells (they communicate with each other), which gives it better ventilation and above all a superior ability to recover its shape after compression. This is THE foam of the professional market. Density from 24 to 50 kg/m³ depending on use.

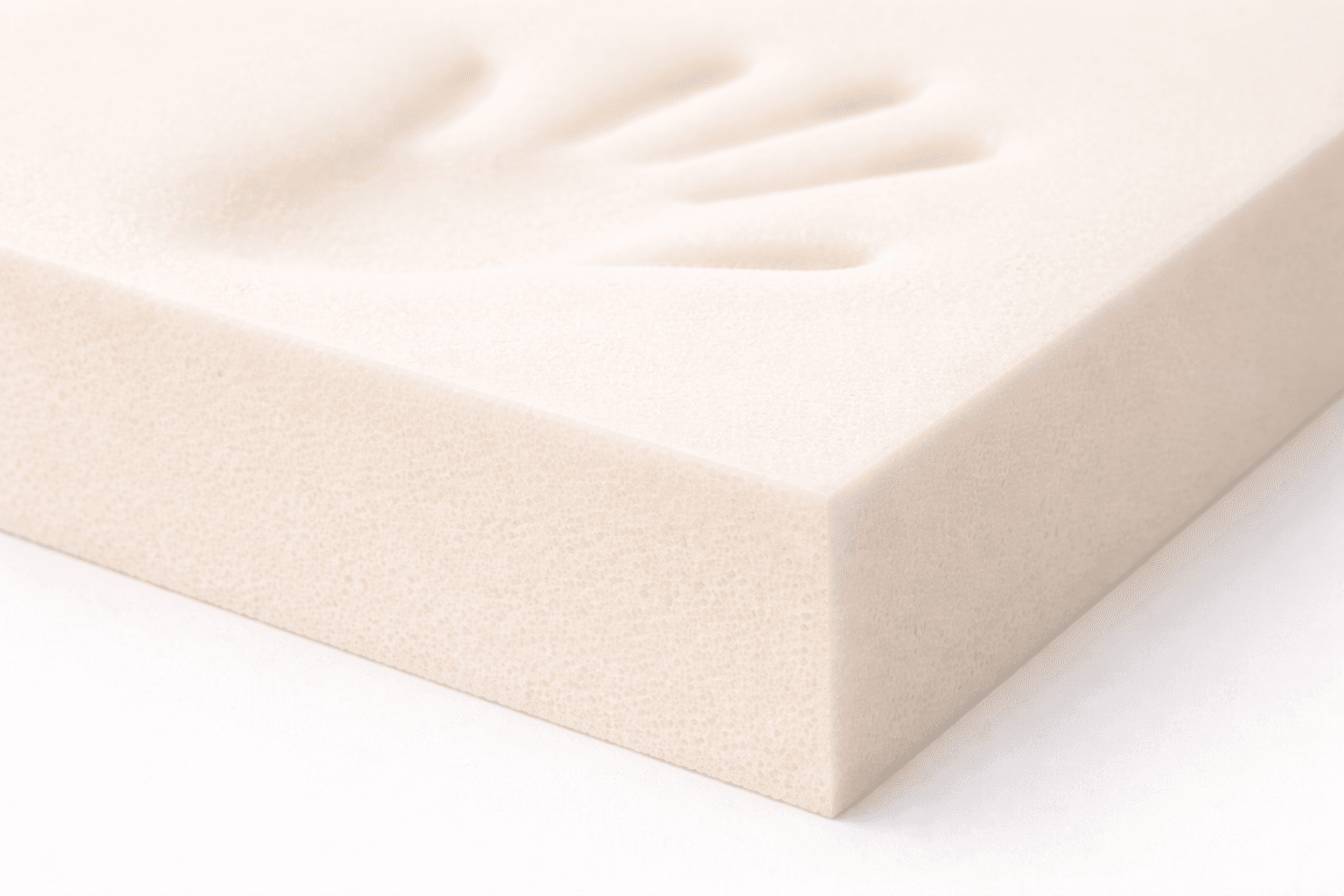

Viscoelastic foam

Viscoelastic foam (memory foam): a polyurethane foam enhanced with additives that make it thermosensitive. It reacts to body heat and perfectly conforms to contours. NASA invention, popularized by Tempur. Dense (50-85 kg/m³) but not very reactive – it takes time to recover its shape. I almost never use it for sofas: too soft for seating used daily.

How is it made?

The basic polyurethane recipe:

- Polyols (petroleum derivatives, or partially from soy/castor for “bio” versions)

- Isocyanates (the chemical reactant)

- Blowing agents (which create the bubbles – used to be CFCs, now water or CO2)

- Additives (stabilizers, catalysts, colorants, flame retardants)

Mix it all together, it foams like a giant meringue, hardens in a few minutes, and you get a block of foam. Then cutting, drying, quality control.

Molded foam (process)

Molded foam is an industrial process used by high-end manufacturers like B&B Italia: the mixture is injected directly into a mold shaped like the cushion. This allows for varying densities within the same block and complex ergonomic shapes. More expensive, but superior results.

So much for the basics. Now that you know what foam really is, we can talk about the real quality differences…

Here’s the Hart Design Selection foam guide. Hang on, some truths will surprise you.

The professional standard: HR foam still reigns supreme

High Resilience foam: the heart of the industry

First ecological disillusionment: the finest workshops in the world massively use HR (High Resilience) polyurethane foam. For example, B&B Italia, worldwide reference of Italian design, bases all its production on “cold-molded polyurethane foam” – their proprietary technology that revolutionized the sector in the 1970s. They guarantee their structures (steel frame wrapped in polyurethane foam) for 10 years.

Here are the recommended uses and densities for HR foams

- HR35 kg/m³: the minimum for a proper sofa seat

- HR40-43 kg/m³: for intensive or professional use

- HR25-30 kg/m³: for backs and armrests (lower density = more flexibility)

Bultex foams and CertiPUR certified foams dominate the professional market. Home Spirit, a French high-end manufacturer, uses “Bultex 35 kg/m³” as the basis for its Gold collections.

Firmness matters more than density

Little upholsterer’s secret: density alone means nothing. You can see HR30 foams that are firmer than HR40. Why? Because professionals actually think in KPA (Kilo Pascal): the force needed to compress the foam by 40%.

Resilience (ability to recover its shape) is measured by a ball rebound test: you drop a steel ball and measure the bounce height. A real HR shows 45 to 70% rebound, versus 20-40% for low-quality foam.

This number, you’ll never find on the store label, but it’s what makes the difference between a sofa that sags in 2 years and one that lasts 15 years.

And what about toxicity?

Let’s be frank: polyurethane is chemically transformed petroleum. What does it smell like when you unpack a new sofa? Those famous VOCs (Volatile Organic Compounds) that escape during the first weeks.

The truth? Uncertified low-quality foams can release not-so-great substances: formaldehyde, toluene, benzene.

These labels guarantee:

- Absence (or very low level) of heavy metals

- VOC limitation

- No prohibited carcinogenic or allergenic substances

- No phthalates, pesticides, toxic flame retardants

That’s why you must systematically require CertiPUR and Oeko-Tex Standard certifications. It’s our health that’s at stake, not just that of furniture professionals.

After a few weeks of aeration, certified foam is considered safe for home use. But I won’t lie to you: you’ll always have minimal chemical residues. It’s plastic, period. For a truly sensitive customer (allergies, asthma, young children), I recommend natural latex or springs + coco. It costs more, but nobody gets poisoned.

Absolute luxury: the art of multi-layers and feathers

The high-end standard: polyurethane + goose down

Second revelation: even at €10,000 per sofa, Flexform, Cassina and Poltrona Frau don’t only use “natural” materials.

Their magic recipe combines:

- Molded polyurethane foam base (the structure)

- Envelope in sterilized goose down certified Assopiuma (Gold label)

- Anti-sagging insert in non-deformable material in the center

The Groundpiece model from Flexform (their €8000+ bestseller) offers a choice of:

- 100% goose down cushions with internal reinforcement

- OR polyurethane foam + Dacron cushions

Why this foam + feather combination? Because feathers alone sag. They’re beautifully soft, but without structural support, your seat becomes a pancake in 6 months. Foam provides support, feathers provide comfort.

Professional tip: if you opt for feather seats or backs, demand interior compartmentalization. Without it, disaster is guaranteed. Feathers naturally migrate to the edges under the effect of pressure and movement. Result: the center of the cushion becomes flat as a pancake and the edges swell uselessly.

Compartmentalization (internal vertical seams that create compartments) keeps feathers evenly distributed. It’s what makes the difference between a cushion that keeps its loft for 15 years and one that’s flat in 2 years.

Backs: where feathers triumph

Unlike seats that require support, high-end backs can afford:

- Compartmentalized goose feathers (100%) – the absolute top

- OR 32mm hollow silicone polyester fiber balls

Backs in foam alone? Too “dry” to the touch for true luxury. An HR25 yes, but wrapped in wadding at minimum.

Bio-sourced alternatives: the reality on the ground

When a customer asks for “soy,” I explain the truth: so-called “soy” foams contain 15 to 25% maximum soy oil. The remaining 75-85%? Good old petroleum-sourced polyurethane.

It’s a real ecological progress (carbon footprint -20%), but let’s call a spade a spade: this is NOT natural foam (and it’s +15-20% extra cost for 20% soy).

The gain is mainly environmental (renewable resource), not health-related. In the workshop, the smell and dust are identical.

Castor oil foam: for memory foam

Castor enters viscoelastic foam formulations (memory foam). The French brand Biotex offers “Mémo Sensitive Visco Végétale” foams with 20-40% castor.

Appreciable advantage: unlike classic memory foams that harden in the cold (a nightmare in winter), those with castor maintain their flexibility regardless of temperature. Density 40-55 kg/m³.

Problem: it’s too soft for a seat that must support weight daily. It sags. It’s perfect for mattresses, not for a family sofa.

Orbis recycled foam: the real circular innovation

Now, this is a technology that really interests me. Vita (Recticel group) recovers 200,000 used French mattresses per year and chemically “depolymerizes” them to recover the polyols (the foam base). These recycled polyols replace 20-30% of new polyols.

Result: performances strictly identical to new foams, equivalent price, certifications maintained (CertiPUR). I use it when I can, but not all my suppliers offer it yet. It’s still niche.

Toxicity? Identical to certified new foam. Recycling is done at very high temperature (200-400°C), which eliminates any health risk according to tests. In handling, no difference from new foam.

100% natural exists: latex and coconut fiber

Natural latex: the ecological luxury that works (and smells good!)

I recently tested natural latex with Escot, and honestly, I loved the comfort. 85-97% pure latex (rubber tree sap), with GOLS certification, offers incomparable touch and elasticity. Density 65-85 kg/m³, naturally ventilated honeycomb structure, advertised lifespan of 15-20 years.

The comfort is there: neither too firm nor too soft, a perfect balance between support and welcome. The foam really “breathes,” no feeling of overheating even after hours of sitting. And the naturally antibacterial and hypoallergenic aspect reassures my sensitive customers.

But what amazed me as a professional is the smell – or rather the absence of smell. When I cut natural latex, it smells… nothing. Or rather a slight vegetal odor, almost pleasant. Zero aggression for the nose. Sanding dust? It doesn’t irritate my respiratory tract. It’s night and day compared to polyurethane foam. After a day working with latex, I don’t have a headache. It’s life-changing.

Toxicity-wise? This is where natural latex really shines. Zero VOCs, zero petrochemical products, zero synthetic allergens. GOLS certification guarantees >95% pure latex, the rest being natural vulcanizing agents necessary for solidification. It’s naturally antibacterial, anti-mite, hypoallergenic. For a baby, an allergic person, or someone who really wants healthy materials, it’s the absolute ideal.

But the price is unequivocal: 3 times more expensive than a classic HR35. We go from €40-60 per m² for my usual foam to €150-250 per m² for quality natural latex. On a 3-seater sofa, that inflates the budget by a minimum of €800-1000 just for upholstery.

Conclusion: choosing with full knowledge

After this complete overview, one thing is clear: there is no perfect solution, only informed compromises. The “all natural” accessible to everyone is a marketing fantasy. Latex and coconut fiber exist, but their price reserves them for an informed clientele with a substantial budget.

For the majority of sofas, CertiPUR certified HR polyurethane foam remains the best compromise between performance, durability and price. It’s not ecological in the strict sense, but a quality HR35 or HR40 that lasts 15 years remains more virtuous than a low-quality foam to replace every 3 years.

My final advice? Always prioritize certifications (CertiPUR, Oeko-Tex) for your health and that of your artisans. Demand transparency on densities and compositions. And if you have the budget, invest in natural latex or the traditional springs + coco technique – your body and the planet will thank you for 20 years.

And above all, remember: a good sofa is one that matches YOUR needs, your budget, and your values – not necessarily the one from the high-end catalog you’ll never be able to afford, nor the discount one that will sag in two years.

Digital entrepreneur and craft artisan.

My work bridges craftsmanship, design history and contemporary creation, shaping a personal vision of luxury interior design.

Since 2012, I have been based in my workshop on the shores of Lake Annecy, creating bespoke interiors for architects, decorators and private clients.