Wood and design guide

Table of Contents

Wood constitutes the only truly renewable natural material capable of spanning centuries without losing its nobility. From Egyptian sarcophagi in ebony and cedar four millennia old to contemporary Scandinavian creations celebrating ash and light oak, this material accompanies humanity in its aesthetic and functional history. Geographically and culturally universal, it embodies both ancestral artisanal tradition and the most contemporary technical innovation. No civilization has been able to do without wood to build its habitat, shape its furniture, express its decorative creativity.

Our era marks a spectacular return to natural materials and a disinterest in omnipresent synthetic materials. Wood reaffirms its legitimacy as a choice that is simultaneously aesthetic, technical and ethical.

Contemporary innovations (cross-laminated timber for high-rise construction, ecological thermal treatments, rigorous forestry certifications) demonstrate that tradition and modernity never oppose each other. They mutually enrich to propose performant and responsible solutions.

This guide explores the complete universe of wood in design and decoration. Detailed panorama of noble European species, refined fruit woods and local alternatives to questionable exotics. Traditional and contemporary finishes that reveal or transform the material. Infinite applications from furniture to architecture. Professional selection criteria integrating technical performance and environmental responsibility. The objective: to offer you the keys for informed, sustainable and inspired choices, capable of transforming your projects into timeless creations.

History of Wood in Design: From Millennial Craftsmanship to Contemporary Innovation

Antiquity and Middle Ages: The Foundations of Cabinetmaking

Ancient Egypt already mastered remarkable cabinetmaking techniques. Pharaonic tombs reveal furniture in ebony imported from Africa and cedar from Lebanon, assembled with stunning precision. Marquetry, veneer, mortise and tenon joints: Egyptian artisans developed expertise that would span millennia. Ancient Greece then Rome codified the first furniture styles: the Greek klismos with elegant curved legs, Roman triclinium for banquets, established formal typologies that would influence the entire history of design.

The Middle Ages privileged solid oak for its robustness and availability in Europe. Monumental chests, carved cabinets, paneled seats: medieval furniture celebrated mass and permanence. Assembly techniques were perfected, making it possible to create large solid pieces without metal nails. Carved motifs – linen fold, Gothic rosettes – testified to decorative virtuosity that transformed wood into vegetable stone.

Renaissance and Classical Periods: Decorative Zenith

The Italian Renaissance revolutionized cabinetmaking with marquetry and Florentine intarsia. These techniques made it possible to create true paintings in wood, composed of hundreds of meticulously cut and assembled pieces. Trompe-l’oeil architectural perspectives, still lifes, complex geometric motifs transformed furniture facades into precious works of art. Italian walnut, with its fine grain and warm color, became the wood of choice for this period.

17th and 18th century France brought cabinetmaking to its absolute summit. Under Louis XIV, André-Charles Boulle invented Boulle marquetry combining tortoiseshell, brass and precious woods in spectacular compositions. Louis XV furniture celebrated graceful curves, exotic woods – rosewood, bois de rose – and chiseled gilded bronzes. Under Louis XVI, the return to antiquity favored straighter lines, mahogany veneer, neoclassical motifs. Techniques reached unequaled perfection: invisible joints, extremely fine veneers, stupefyingly delicate carvings.

19th Century: Industrial Revolution and Technical Innovations

Industrialization radically transformed furniture production. Machine tools enabled mass production, democratizing access to quality furniture. Michael Thonet revolutionized design with his chair No. 14 created in 1859: beech wood bent with steam, simplified assembly with six screws, mass production reaching 50 million units. This technical innovation opened the way to modern design, reconciling aesthetics, functionality and economic accessibility.

The end of the 19th century saw the invention of industrial plywood, a revolutionary composite material. By gluing several sheets of wood with crossed fibers, a dimensionally stable, resistant and economical panel was obtained. This technical innovation would make possible the formal audacities of 20th century modernist design. Art Nouveau exploited the decorative possibilities of wood with its organic curves inspired by nature, while machines made it possible to industrially reproduce what previously came from artisanal sculpture.

20th Century: Modernism and New Forms

The German Bauhaus, in the 1920s, established the principles of modern functionalism. Wood combined with chrome-plated tubular steel in Marcel Breuer’s creations. Molded plywood allowed organic forms impossible with solid wood. This revolutionary approach valued the truth of materials, refusing superfluous ornamentation to celebrate the intrinsic beauty of structure and material.

The post-war period saw the explosion of Mid-Century design, a movement that completely reinvented wood furniture. Charles and Ray Eames masterfully exploited molded plywood in their iconic creations: LCW and DCW chairs with fluid organic forms, Lounge Chair combining rosewood and leather. Scandinavian designers – Alvar Aalto in Finland, Hans Wegner and Arne Jacobsen in Denmark, Bruno Mathsson in Sweden – celebrated light Nordic woods with a philosophy blending functionality, comfort and accessible beauty. Burmese teak became the emblematic wood of this period, before ecological questions challenged its use.

Contemporary: High-Tech and Responsibility

Contemporary design explores the infinite possibilities offered by new technologies while reaffirming the importance of environmental responsibility. Cross-laminated timber (CLT) now makes it possible to build towers of several dozen floors entirely in wood, revolutionizing urban architecture. London, Oslo, Vancouver see the rise of high-rise buildings in solid wood, demonstrating the exceptional structural performance of this millennial material revisited by contemporary technology.

Thermally modified wood offers an ecological alternative to exotic species. Heated to high temperature without oxygen, common European wood acquires durability, stability and color comparable to tropical woods, without toxic chemical treatment. FSC and PEFC certifications guarantee responsible forest management, responding to growing eco-responsibility requirements. Contemporary design thus reconciles technical innovation, aesthetic excellence and environmental respect, a triple requirement that defines our creative era.

Major Wood Species Families: Complete Panorama

Each wood species possesses its own identity, its aesthetic and tactile character, its specific technical properties. Knowing these particularities allows choosing the ideal wood for each application, balancing beauty, performance and responsibility.

European Noble Woods: Excellence and Accessibility

Oak: Timeless Robustness

Oak has reigned for centuries as the king of European woods. Its exceptional hardness, impact resistance, richness in natural tannins that protect it from insects and rot make it remarkably long-lasting wood. Its pronounced grain, characteristic medullary rays creating shimmering reflections, and its color evolving from golden honey to warm brown with time give it noble and reassuring beauty.

Two main species in Europe: sessile oak (Quercus petraea) with finer and more regular grain, prized for quality furniture and cooperage; pedunculate oak (Quercus robur) slightly softer, excellent for construction and floors. American white oak (Quercus alba) offers similar characteristics with a slightly lighter shade. French oak forests – Tronçais, Fontainebleau, Vosges – produce exceptional woods recognized worldwide.

Preferred uses: solid and engineered floors for wear resistance, traditional and contemporary furniture in solid wood or veneer, frames and structural elements for solidity, cooperage for aromatic qualities, exterior joinery for natural durability.

Aging: Oak develops a magnificent golden patina, enriching over the years. Antique solid oak furniture crosses generations as living heritage. Indicative price: 50-80€/m² in flooring, 800-1500€/m³ in timber – accessible for noble wood of this quality.

Walnut: Chocolate Elegance

Walnut immediately seduces with its deep chocolate brown color, elegant veining that meanders through the wood like dark rivers, its fine and tight grain that makes it extraordinarily soft to the touch. Easy to work, dimensionally stable, it authorizes delicate carvings and precise joints. Its light sapwood contrasts with the dark heartwood, allowing subtle decorative effects.

European walnut (Juglans regia) offers the richest and most varied colorations, from light brown to almost black, with spectacular purple or gray veins. American walnut (Juglans nigra – Black Walnut), slightly more uniform, presents a characteristic brown-purple shade and constitutes a well-managed resource in North America, widely available with FSC certification. Unlike some exotic woods, American walnut poses no ecological problem and fits into sustainable silviculture. The finest walnut logs, with wavy or burled grain, reach exceptional prices reserved for luxury veneer.

Preferred uses: high-end solid wood furniture for masterpieces, precious veneer on buffets and dressers to optimize finest veinings, turning for decorative objects thanks to its fineness, gun stocks for stability and touch, lutherie for certain instrument parts.

Stylistic history: Favorite of Louis XV furniture for elegant curves, rediscovered by Art Deco celebrating dramatic contrasts, still prized in contemporary design for natural sophistication. Indicative price: 2000-4000€/m³ – investment justified by beauty and rarity.

Ash: Brightness and Resilience

Ash is distinguished by its light color – cream white to golden blond – and elegant grain marked with regular brown veins creating delicate natural graphics. Its hardness comparable to oak is accompanied by remarkable elasticity that allows it to bend without breaking, a quality exploited since Antiquity to make bows, tool handles, tennis rackets. This exceptional mechanical flexibility makes ash both robust and resilient wood.

European ash (Fraxinus excelsior) dominates in France, while American white ash (Fraxinus americana) offers similar characteristics with a slightly more uniform shade. Unfortunately, ash dieback – a fungal disease that appeared in Europe in the 2000s – seriously threatens ash populations, making quality available woods all the more precious.

Preferred uses: Scandinavian and minimalist contemporary furniture for luminous clarity, floors and stairs for wear resistance, tool handles and sports articles for elasticity, decorative veneer for graphic grain, steam bending for flexibility.

Aesthetics: Ash embodies Nordic modernity: luminous without being cold, graphic without ostentation, robust without heaviness. Highly prized in contemporary Scandinavian design. Indicative price: 60-90€/m² in flooring, 600-1200€/m³ – excellent quality-price ratio for noble wood.

Beech: Discreet Versatility

Beech presents a pinkish white to light brown color, very fine and regular grain, homogeneous texture without marked veining. Dense and hard, it offers excellent wear resistance while remaining relatively easy to work. Its remarkable capacity to bend with steam made it Michael Thonet’s wood of choice for his legendary chairs. Non-duraminized – its sapwood and heartwood are undifferentiated – it stains easily and uniformly.

European beech (Fagus sylvatica) constitutes the second most abundant hardwood species in France after oak. This availability, combined with excellent mechanical properties, makes it economical and performant wood, unfortunately often underestimated in contemporary furniture while offering remarkable qualities.

Preferred uses: chairs and seats, notably Thonet icons and bent furniture, modern and contemporary furniture, floors for hardness, toys for fineness and non-toxicity, kitchen utensils and cutting boards, quality plywood.

Technical particularity: Excellent support for staining and lacquering, allowing imitation of other species or creation of uniform colored finishes. Indicative price: 40-70€/m² in flooring, 400-800€/m³ – the most economical noble wood, exceptional quality-price ratio.

Maple: Luminous Whiteness

Maple fascinates with its very light color, almost white, sometimes slightly cream, which brings exceptional brightness to spaces. Its fine and regular grain, tight and homogeneous texture give it remarkable tactile softness. Its exceptional hardness – comparable or even superior to oak – resists abrasion particularly well, a quality exploited for dance floors, butcher worktops, bowling lanes.

Several species of interest: European sycamore maple (Acer pseudoplatanus) with immaculate white, curly maple whose fibers create spectacular shimmering effect sought after for lutherie and precious veneers, North American sugar maple (Acer saccharum) slightly harder. The finest pieces of curly or flamed maple – moiré veinings creating light plays – reach very high prices.

Preferred uses: dance and gymnasium floors for intensive wear resistance, professional butcher and kitchen worktops, minimalist contemporary furniture for clarity, guitar necks and violins for curly maple, decorative object turning for fineness.

Aesthetics: Embodies Nordic purity and contemporary minimalism. Creates luminous and airy interiors. Pairs perfectly with white and pastel tones. Indicative price: 70-100€/m² in flooring, 800-1500€/m³, up to 5000€/m³ for exceptional figured maple.

Birch: Scandinavian Luminosity

Birch embodies the essence of Scandinavian design. Its cream white to pale yellow color, fine and regular grain, silky texture make it luminous wood particularly prized in Nordic countries where natural light is scarce. Relatively soft, easy to work, it lends itself remarkably well to steam bending and molded plywood, techniques that Alvar Aalto masterfully exploited in his emblematic creations.

European birch (Betula pendula and Betula pubescens) dominates in Scandinavia and Russia. Its rapid growth – 40 to 60 years – makes it an abundant renewable resource. North American yellow birch (Betula alleghaniensis), slightly harder, offers similar characteristics. The characteristic white bark of birch, although rarely preserved on furniture, inspires many contemporary decorative creations.

Preferred uses: molded plywood for design furniture (Aalto technique), contemporary Scandinavian furniture for clarity, decorative veneer, object turning, tool handles for lightness, floors in refined Nordic style.

Iconic design: Alvar Aalto made Finnish birch his material signature. His furniture from the 1930s-40s celebrates organic curves made possible by molded birch plywood. Indicative price: 50-80€/m² in flooring, 600-1000€/m³ – accessible and local in Northern Europe.

Fruit Woods: Fineness and Sophistication

Cherry (Wild Cherry): Golden Warmth

Cherry – or wild cherry for its European wild variety – seduces with its warm color oscillating from golden pink to reddish brown, fine and tight grain, silky texture to the touch. What makes it particularly precious: its capacity to darken magnificently with time and light exposure. A relatively light new cherry furniture piece will progressively develop deep and warm red tones, noble patina that considerably enriches its character.

European wild cherry (Prunus avium) offers the finest veinings, while American cherry (Prunus serotina) presents a slightly redder initial color. Medium hard, easy to work, dimensionally stable, it lends itself to both solid furniture and decorative veneer. Its characteristic small knots, far from being defects, add authenticity and refined rustic charm.

Preferred uses: traditional and contemporary high-end furniture, decorative veneer on buffets and dressers, turning for precious objects, lutherie for certain instruments, decorative panels and paneling, floors in prestigious residential spaces.

Temporal evolution: Cherry patina constitutes a major sales argument. A relatively pale new piece transforms over 5-10 years into piece with deep mahogany tones, extraordinary natural appreciation. Indicative price: 1500-3000€/m³ – investment that literally appreciates with time.

Pear: Exceptional Fineness

Pear represents the discreet aristocracy of fruit woods. Its exceptionally fine and tight grain – the finest among common European woods – allows stupefyingly delicate carvings and incomparably smooth finish. Its delicate pinkish color, sometimes tending toward light brown, offers sober and refined elegance. Dense and heavy, it works with remarkable precision.

Relatively rare in large dimensions – fruit pear trees rarely reach oak size – pear remains precious wood used mainly for applications requiring fineness and precision rather than volume. This rarity, combined with exceptional qualities, makes it sought-after and expensive material, reserved for exceptional creations.

Preferred uses: fine marquetry for cutting precision, delicate sculpture and engraving, musical instruments for stability and grain, high-end kitchen utensils, precision tool handles, stained black as ebony substitute for certain applications.

Historical particularity: Blackened pear imitated ebony in antique cabinetmaking, its fine grain allowing similar finish. Still used today for this application in antique furniture restoration. Indicative price: 3000-5000€/m³ – rare and precious, justified by unique qualities.

Exotic Woods: Luxury and Ethical Questions

Environmental warning: Tropical woods pose major ecological problems related to deforestation, biodiversity destruction and long-distance transport. Before any purchase, imperatively verify strict FSC certifications and CITES permits when necessary. In the vast majority of cases, European alternatives (see next section) offer equivalent performance with infinitely lower environmental impact.

Teak: Natural Rot-Resistance

Teak owes its worldwide reputation to a unique characteristic: its exceptional richness in natural oils that make it practically rot-proof, even in prolonged immersion. This extraordinary property explains its traditional use in naval construction – boat decks, hulls – and its success for garden furniture. Its golden honey color, regular grain, remarkable dimensional stability complete its technical qualities.

Native to Southeast Asia (Burma, Thailand, Indonesia), teak (Tectona grandis) was massively overexploited in the 20th century. Natural forests have largely disappeared, replaced by plantations whose quality and environmental practices vary considerably. FSC certification remains essential but insufficient to guarantee truly responsible provenance.

Traditional uses: high-end garden furniture, floors including wet rooms, naval construction and boat decks, exterior terraces, bathrooms for water resistance.

Recommended alternative: French black locust (false acacia) offers equivalent or even superior durability, without any negative environmental impact. Thermally treated oak also constitutes an excellent alternative. Indicative price: 3000-6000€/m³ – high cost technically justified but ecologically questionable.

Ebony: Threatened Deep Black

Ebony embodies absolute luxury and extreme preciousness. Its deep black, uniform, without light sapwood, its exceptional density that makes it sink in water, its capacity to polish like stone to mirror shine make it unique material. Extremely hard, difficult to work, it produces fine characteristic black dust when cut.

Several species of the genus Diospyros provide true ebony: Diospyros ebenum from India and Sri Lanka, African ebonies from Madagascar and Central Africa. All are now seriously threatened by overexploitation. Madagascar has lost most of its ebony forests, plundered by international mafia trafficking. Ebony appears on CITES lists with strict controls, but illegal trade persists.

Historical uses: luxury marquetry and inlay, piano keys (now replaced by resins), precious objects and small ceremonial furniture, sculptures and art objects, high-end knife handles.

Ethical recommendation: Absolutely avoid ebony except irreproachable certified provenance and absolutely essential use. Alternatives: black-stained pear for fine grain, lacquered black local woods for aesthetics. Indicative price: 8000-15000€/m³ and more – prohibitive price reflecting rarity but unfortunately encouraging trafficking.

Rosewood: Strict Regulation

The term rosewood designates several species of the genus Dalbergia distributed in South America, Africa and Asia. Their spectacular veinings – purple, black, violet veins on brown background – their characteristic perfume, their exceptional hardness and their capacity to take magnificent polish explain their luxury wood status. Rio rosewood (Dalbergia nigra), the most prized, presents striking chromatic contrasts.

Since 2017, all Dalbergia species are listed in CITES Appendix II, meaning their international trade requires export and import permits. This regulation follows decades of overexploitation having led several species to the brink of extinction. Illegal trafficking nevertheless persists, particularly for Asian rosewood destined for the Chinese traditional furniture market.

Traditional uses: exceptional furniture and luxury cabinetmaking, precious veneer for decorative surfaces, high-end musical instruments (guitars, pianos), art object turning, knife handles and precious objects.

Recommended alternative: European walnut offers warm brown tonalities and elegant veinings without environmental problematic. Cherry can also suit certain applications. Indicative price: 5000-12000€/m³ depending on species and quality – very high, absolutely verify CITES permits.

Wenge: Dramatic Contrasts

Wenge (Millettia laurentii) from Central Africa fascinates with its spectacular chromatic contrasts. Very dark brown, almost black, streaked with deep black veins, it creates powerful and contemporary graphic effect. Very hard, coarse grain, it works with difficulty but offers excellent durability. Its color darkens further with time, evolving toward uniform black.

Massively exploited in the 1990s-2010s for floors and contemporary design furniture, wenge has seen its natural populations drastically reduced. Although it is not (yet) under strict CITES regulation, its overexploitation poses serious environmental questions, especially since its transport from Central Africa generates considerable carbon footprint.

Common uses: floors for graphic contrast, contemporary design furniture, decorative veneer on doors and panels, decoration elements for dramatic aspect.

Recommended alternative: Black-stained oak or ash offers similar aesthetics. Dark thermally treated oak also constitutes a sustainable option. For graphic aspect: play on sapwood/heartwood contrasts of local woods. Indicative price: 2500-4500€/m³ – technically justified but ecologically questionable, absolutely prioritize alternatives.

Eco-Responsible Local Woods to Rediscover

Faced with environmental problems of exotic woods, French and European local species deserve complete reevaluation. Modern thermal treatment technologies, innovative finishing techniques and rediscovery of long-neglected properties demonstrate that these “common” woods offer remarkable performance for minimal ecological footprint.

Black Locust (False Acacia): Unrecognized Champion

Black locust (Robinia pseudoacacia) deserves the title of unrecognized champion of European woods. Only wood from our regions naturally classified in durability class 1 (very durable, resistance exceeding 25 years outdoors) without any treatment, it surpasses teak in longevity. Harder than oak, naturally rot-proof thanks to its tannins and flavonoids, it resists insects, fungi, prolonged humidity. Its characteristic yellow-green color evolves into natural silvery gray outdoors.

Native to North America, black locust naturalized in Europe since the 17th century and now widely colonizes France, offering abundant and renewable local resource. Its relatively rapid growth – 40 to 60 years for mature tree – allows sustainable forest management. Its main “defect”: a misleading name (“false acacia”) that harms its image, when it has nothing “false” and far surpasses true acacia in technical qualities.

Recommended uses: exterior terraces replacing teak, ultra-durable garden furniture, children’s playgrounds (naturally non-toxic), stakes and posts (exceptional lifespan), exterior construction and cladding, floors for hardness.

Why so unrecognized? Image of “common wood”, unflattering name, uneven availability, frequent knots. Yet, technically superior to teak for outdoors, local, ecological, economical. Indicative price: 80-120€/m² in terrace decking, 600-1000€/m³ – unbeatable performance/price/ecology ratio, ideal alternative to teak.

Douglas Fir: Architectural Renaissance

Douglas fir (Pseudotsuga menziesii), softwood native to North America but widely planted in France since the 19th century, experiences spectacular renaissance in contemporary architecture. Its characteristic pinkish to orange color, pronounced and regular grain, excellent mechanical resistance, correct natural durability (class 3, improvable to class 2 by thermal treatment) make it versatile and aesthetic construction wood.

French Douglas fir forests – particularly in the Massif Central and Landes – today produce high-quality woods. Its rapid growth (50-60 years) allows sustainable and productive silviculture. Contemporary architecture rediscovers its qualities: warm color, machining ease, excellent strength/weight ratio, availability in large sections.

Expanding uses: frames and wood framing for structural resistance, exterior cladding (with or without treatment), terraces in thermally treated Douglas fir, contemporary furniture for distinctive color, CLT (cross-laminated timber) for high-rise construction, interior paneling and cladding.

Architectural trend: Major contemporary wood architecture projects massively use French Douglas fir. Residential towers, public facilities, collective housing celebrate its warm color and structural performance. Indicative price: 50-80€/m² in cladding, 400-700€/m³ – very economical for its qualities, 100% local and renewable.

Chestnut: Mediterranean Tradition

Chestnut (Castanea sativa) shares with oak a precious characteristic: richness in natural tannins that effectively protect it from rot and insects. Durability class 2 without treatment, it resists remarkably well in exterior use. Its honey to light brown color, grain similar to oak but without characteristic medullary rays, its relative lightness make it versatile and economical wood.

Traditional in Mediterranean regions and southern France, chestnut has long supplied vineyard stakes, frame beams, roof shingles. Its cultivation and harvesting fit into centuries-old local tradition. Today rediscovered for its ecological qualities – local species, resistant, abundant – it deserves prominent place in responsible projects.

Relevant uses: exterior joinery (windows, shutters) for stability and durability, traditional and contemporary frames, exterior cladding and siding, posts and stakes (25+ year lifespan), rustic and contemporary furniture, floors in authentic style.

Ecological asset: Local Mediterranean and Atlantic species, sustainable traditional forest management, short circuit possible, credible alternative to certain exotic wood uses. Indicative price: 60-90€/m² in cladding, 500-900€/m³ – excellent quality/price/ecology ratio, valorization of French forest heritage.

Pine: Accessibility and Versatility

Pines – maritime pine (Pinus pinaster) in the Landes, Scots pine (Pinus sylvestris) in mountain massifs – constitute the most abundant softwood resource in France. Soft woods, easy to work, economical, they traditionally serve construction, common joinery, packaging. Their characteristic knots, pronounced grain, light yellowish color create authentic rustic aesthetics.

Long considered “common” or even low-grade woods, pines experience reevaluation in responsible and accessible design perspective. Accept their natural aesthetics – knots, resin, marked grain – rather than seeking to mask them. Value their local availability, moderate cost, minimal carbon impact. Treat them thermally or with autoclave for durable exterior uses.

Multiple uses: construction and framing (historical use), rustic and assumed contemporary furniture, interior paneling and cladding for warm ambiance, terraces in treated autoclave pine, interior joinery, plywood and derived panels, packaging and pallets (possible second life in upcycled furniture).

Usage philosophy: Assume natural aesthetics of pine rather than seeking to imitate noble wood. Honest design, accessible material, renewable, local. Perfect for budget-controlled projects without ecological compromise. Indicative price: 30-60€/m² in paneling, 300-600€/m³ – the most economical of local woods, democratization of solid wood.

Spruce: Construction and Lutherie

Spruce constitutes the softwood of construction par excellence in Europe. Its yellowish white to pinkish light color, fine and regular grain, lightness combined with remarkable mechanical resistance make it versatile and economical structural wood. Soft, easy to machine, it works easily while offering sufficient mechanical properties for framing, framework, joinery.

European common spruce (Picea abies) dominates in mountain massifs – Alps, Vosges, Jura, Massif Central. A particular variety deserves mention: Alpine resonance spruce, selected for exceptional acoustic qualities. Slow growth at altitude, extraordinarily regular grain, absence of knots: these exceptional spruces have supplied soundboards of the most prestigious violins, guitars, pianos for centuries. Stradivarius already used Alpine spruce in the 18th century.

Multiple uses: frames and wood framing (main use), interior paneling and cladding, interior joinery, economical and rustic furniture, structural plywood, glued laminated timber for large spans, instrument soundboards (resonance quality).

Advantages: Very abundant in France and Europe, rapidly renewable, excellent strength/weight/price ratio, machining ease, usage versatility. Indicative price: 35-60€/m² in paneling, 350-600€/m³ – among the most economical, ideal for accessible ecological construction.

Larch: Alpine Resistance

Larch stands out among softwoods for exceptional natural durability. Only European softwood losing its needles in winter, it develops dense wood, hard for a softwood, naturally resistant to weather, fungi, insects. Its characteristic red-orange to reddish-brown color, pronounced marked grain, frequent knots create warm rustic aesthetics particularly prized in mountain architecture.

European larch (Larix decidua) grows in the Alps and other mountain massifs, at altitude where difficult conditions produce slow-growing and therefore very dense wood. This density superior to other softwoods gives it natural durability class 3-4 without treatment, allowing durable exterior uses. Siberian larch, close variety, offers similar or even superior characteristics.

Privileged exterior uses: facade cladding and siding (natural durability), exterior terraces (Douglas alternative), exposed frames and frameworks, exterior joinery, garden furniture, landscape developments (stakes, fences).

Aesthetic particularity: Its pronounced orange color naturally evolves toward noble silvery gray outdoors. Accept this natural patina or apply saturator to maintain original wood shade. Indicative price: 70-100€/m² in cladding, 600-900€/m³ – more expensive than Douglas but superior durability, 100% Alpine.

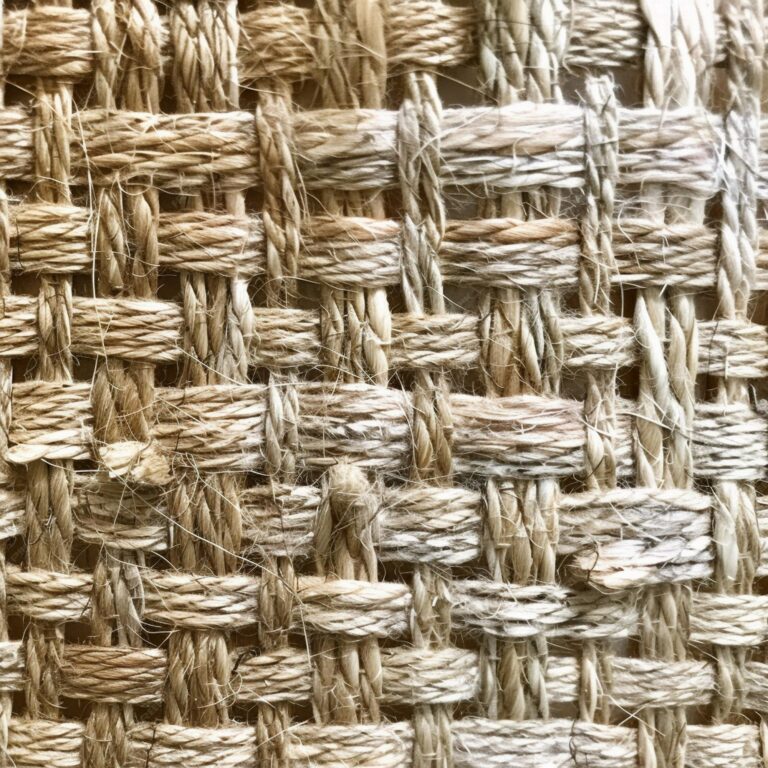

Bamboo: High-Performance Grass

Bamboo, technically a giant grass rather than true wood, deserves its place in this guide through its extensive uses in design and construction. Its exceptionally rapid growth – some species grow a meter per day, maturity reached in 3-5 years versus 50-100 years for trees – makes it renewable resource par excellence. Hard, resistant, dimensionally stable after appropriate treatment, bamboo offers remarkable performance.

Native to Asia, bamboo is cultivated in managed plantations, avoiding deforestation problems of natural forests. Its carbon footprint remains favorable despite transport: ultra-rapid growth massively storing CO2, no deforestation, FSC-certified plantations available. Laminated bamboo – compressed and glued bamboo strips – creates very dense, stable material adapted to floors and worktops.

Contemporary applications: engineered floors (hardness superior to oak), kitchen worktops, contemporary design furniture, light structures and constructions, decorative wall coverings, objects and accessories.

Ecological advantages: Ultra-rapid growth = highly renewable resource, managed plantations (no deforestation), exceptional CO2 sequestration, high durability and technical performance. Indicative price: 60-100€/m² in engineered flooring – competitive with noble woods, ecological if FSC certified.

Finishes and Treatments: Revealing or Transforming the Material

Wood finishing never constitutes a simple technical detail: it determines final aesthetics, touch, durability, necessary maintenance. Choosing between oil, wax, varnish, lacquer radically transforms the character of the same wood. Some finishes reveal and magnify the nature of the material, others completely transform it, opening infinite creative possibilities.

Traditional Finishes: Authenticity and Patina

Oiled: Naturally Nourishing Fibers

Oil penetrates deeply into wood fibers without creating surface film. It nourishes the material, moderately protects against moisture and stains, while completely preserving natural appearance and especially characteristic silky touch of wood. The hand glides on oiled surface with incomparable softness, immediate organic warmth creating privileged tactile connection with material.

Several types of oils: linseed oil, traditional and economical, dries slowly and yellows slightly with time; hard oil, mixture of oils and natural resins, offers superior protection and faster drying; teak oil, specially formulated for oily woods, penetrates even species rich in natural oils; oil-wax, combination of oil and wax, brings protection and satin appearance.

Advantages: 100% preserved natural appearance, exceptional and warm touch, ease of application even for non-professionals, simple local repair (sanding and reoiling area), magnificent patina enriching with time, ecological (natural oils).

Disadvantages: Moderate protection against water and stains, regular maintenance necessary (reoiling 1-2 times/year depending on use), not suitable for very intensive uses, slow drying (24-48h between coats).

Ideal applications: Solid wood furniture where touch matters, kitchen wood worktops (with food-safe oil), dining tables for warm appearance, contemporary furniture celebrating natural, residential floors low to medium traffic.

Waxed: Soft Patina and Ritual Maintenance

Wax, applied in thin layer and buffed with cloth, creates this soft patina characteristic of antique furniture: slightly shiny satin surface, unctuous touch, subtle luminous depth. Traditional beeswax, natural and perfumed, remains reference for antique furniture restorations and high-end finishes. Modern waxes, enriched with carnauba or polymers, offer increased protection.

Waxed wood maintenance constitutes soothing ritual: regular wax application, patient buffing with soft cloth until progressive appearance of delicate shine. This gesture of periodic attention creates particular bond with furniture, awareness of its maintenance and preservation. Patina enriches over years and successive wax passages.

Advantages: Exceptionally beautiful and warm patina, soft and silky touch, grain and veining enhancement, easy repair (wax addition), tradition and authenticity, pleasant beeswax perfume, ecological.

Disadvantages: Very limited protection (sensitive to water and stains), essential regular maintenance (waxing every 3-6 months), white marks if liquid spilled, unsuitable for intensive uses, laborious application (long buffing).

Ideal applications: Antique furniture in restoration, classical or traditional style furniture, desks and secretaries, period paneling and wainscoting, decorative wood objects, ambiances seeking authenticity and time patina.

Varnish: Maximum Protection and Revealed Depth

Varnish creates protective surface film that seals wood and effectively protects it against water, stains, mechanical wear. Transparent, it magnificently reveals wood depth, intensifies colors and veinings, creates according to chosen finish – gloss, satin or matte – very different aesthetic effects. Gloss varnish brings spectacular depth but shows every scratch; satin offers elegant compromise; matte preserves natural appearance while protecting.

Modern technologies: polyurethane varnishes, two-component, offer most performant protection, exceptional chemical and mechanical resistance, ideal for floors and intensive worktops. Water-based acrylic varnishes, less toxic and less odorous, dry quickly and yellow little. Traditional cellulose varnishes, reserved for professionals, allow ultra-fine pad finishes.

Advantages: Maximum protection against water, stains, scratches, wear, spectacular revelation of wood beauty, exceptional durability (10+ years depending on use), minimal maintenance (simple dusting), wide choice of appearances (gloss to matte).

Disadvantages: Less natural touch (surface film), complex repairs (complete sanding often necessary), delicate application (risk of runs, dust), sometimes “plastic” appearance if poorly applied, possible yellowing with time (non-acrylic varnishes).

Ideal applications: Residential and commercial floors for wear resistance, intensively used stairs, work surfaces and worktops, children’s furniture (maximum protection), protected exterior (special marine varnishes).

Contemporary Finishes: Transforming and Personalizing

Lacquered: Smooth Perfection and Infinite Color

Lacquering completely transforms wood by creating perfectly smooth, uniform surface, colored with infinite chromatic possibilities. Ancestral technique from Far East revisited by modern industry, it allows obtaining spectacular mirror finishes or conversely deep and velvety mattes. Lacquering can reveal wood grain (transparent or translucent lacquer) or conversely completely mask it (colored opaque lacquer).

Two approaches: traditional pad lacquering, artisanal, superimposes dozens of fine layers successively sanded to create incomparable depth – patient work reserved for exceptional pieces. Modern industrial lacquering, by spray gun, faster and more economical, nevertheless reaches remarkable qualities with current polyurethane or acrylic technologies. Support preparation conditions 80% of result: meticulous sanding, perfect filling.

Advantages: Refined contemporary or sophisticated classical aesthetics, infinite possible colors (RAL, Pantone), mirror or matte finishes by choice, excellent protection, maintenance ease (simple cleaning), perfect surface uniformity.

Disadvantages: High cost especially for artisanal lacquering, professional application recommended, visible and difficult repairs, masks natural veining if opaque, sometimes “plastic” appearance if poorly executed.

Privileged applications: Contemporary design furniture with refined lines, high-end kitchens (lacquered facades), classical style furniture (Louis XVI white lacquer), precious decorative objects, decorative wall panels, creations requiring specific colors.

Stained: Modifying Color While Preserving Grain

Staining allows modifying wood color while completely preserving visibility and relief of grain and veinings. This technique opens considerable creative possibilities: uniformizing woods from different provenances, imitating noble species with common wood (historical technique: black-stained pear imitating ebony), creating naturally impossible colorations (blue, green, bright red), rejuvenating faded antique furniture.

Types of stains: water-based stains, ecological and low odor, penetrate deeply but slightly swell fibers (intermediate sanding necessary). Alcohol stains dry almost instantly, ideal for quick work but delicate application. Oil or solvent stains, traditional, offer excellent penetration and rich colors. Chemical mordants react with wood tannins to create natural colorations (ammonia on oak = deep brown).

Advantages: Color modification preserving grain and texture, possible uniformization of different woods, infinite chromatic creativity, relatively simple application, moderate cost, deep penetration (no film).

Disadvantages: Sometimes unpredictable result (essential tests), uneven absorption depending on species and grain, difficult to repair (new stain superimposes), requires complementary protection (varnish, oil), can mask defects… or reveal them.

Creative applications: Harmonization of mixed woods in same furniture, graphic effect by selective staining (stained/natural parts), noble species imitation, faded antique furniture rejuvenation, design creations with bright colors (Memphis revival trend).

Shou Sugi Ban (Yakisugi): Japanese Carbonization

This millennial Japanese technique experiences spectacular enthusiasm in contemporary architecture and design. It consists of burning wood surface with torch until partial carbonization, then brushing to eliminate friable residues, revealing black textured, ribbed, striking graphic surface. This carbonization is not just aesthetic: it exceptionally protects wood by making it rot-proof, resistant to UV, insects, fire paradoxically.

Traditionally applied to Japanese cedar for cladding (Yakisugi means “burned cedar”), Shou Sugi Ban is now practiced on various species – Douglas fir, larch, pine – with variable carbonization depths creating effects from deep black to chocolate brown. Some craftsmen then superimpose oil or wax to intensify black and further protect. Others leave raw for more matte and mineral appearance.

Advantages: Spectacular and contemporary graphic aesthetics, exceptional natural protection (50+ year durability), increased fire resistance, ecological (no chemical treatment), almost no maintenance, uniqueness of each piece (natural variations).

Disadvantages: Delicate technique requiring experience, soiling (charcoal black deposits on touch if not protected), irreversible, high cost if artisanally done, may displease (very marked taste).

Trending applications: Contemporary architecture exterior cladding, interior partition and decorative panels, design furniture unique pieces, headboards and graphic wall elements, terraces and landscape developments, carved decorative objects.

Technical Treatments: Durability and Performance

Thermally Treated Wood: Ecological Structural Transformation

High temperature thermal treatment (THT) revolutionizes use of common European woods. Principle: heat wood between 180°C and 230°C in controlled atmosphere without oxygen (steam, nitrogen) for several hours. This treatment profoundly modifies wood chemical structure: elimination of sugars that feed fungi and insects, drastic reduction of hygroscopy (moisture absorption), spectacular improvement of dimensional stability.

Concrete results: common European wood – ash, poplar, beech – reaches after treatment durability comparable to teak (class 2 even class 1), exceptional dimensional stability, uniformly dark color (brown to dark brown depending on temperature and duration). Pine, naturally class 4-5 (not durable), becomes class 2 after thermal treatment. Thermally treated oak technically rivals best exotic woods.

Advantages: Ecological alternative to exotic woods, 100% natural (no chemicals), class 1-2 durability achieved, remarkable dimensional stability, attractive uniformly dark color, European woods transformed into high performance.

Disadvantages: Slightly mechanically weakened wood (10-20% strength loss), slight caramel/smoked odor (disappears), higher price than untreated wood, color limited to browns (no chromatic choice), sometimes drier touch surface.

Ideal applications: Exterior terraces (teak replacement), exterior cladding and siding, durable garden furniture, exterior joinery (windows, doors), bathroom and wet room floors, any application requiring durability without chemicals.

Acetylated Wood: Revolutionary Molecular Modification

Acetylation represents the cutting edge of innovation in wood treatment. Process reacts wood with acetic anhydride (vinegar derivative, non-toxic) which chemically modifies cellulose molecules. Hydroxyl groups (-OH) that absorb water are replaced by hydrophobic acetyl groups. Result: wood becomes incapable of absorbing moisture, therefore dimensionally stable and rot-proof (no water = no fungi or insects).

Accoya brand (acetylated radiata pine) guarantees class 1 durability (50+ years outdoors) with initially non-durable species, 50-year manufacturer warranty, dimensional stability superior even to exotic woods, capacity to take and conserve paints and stains exceptionally long. Only disadvantage: high cost. But extraordinary durability justifies investment over complete life cycle.

Advantages: Absolute class 1 durability (50+ years guaranteed), unequaled dimensional stability, accepts all woods (softwoods transformed into high performance), non-toxic and ecological, preserves natural wood appearance, exceptional manufacturer warranty.

Disadvantages: Very high price (premium), limited availability (one main brand: Accoya), honey color sometimes darker than original wood, slight vinegary odor initially (disappears).

High-end applications: Demanding exterior joinery (windows, doors), prestigious facades and cladding, permanent high-end exterior furniture, bridges and walkways, marine applications, projects requiring exceptional warranty.

Design and Decoration Applications: From Furniture to Architecture

Furniture: From Solid Wood to Derived Panels

Solid Wood: Nobility and Transmission

Solid wood constitutes the ultimate quality in cabinetmaking. Tables, chairs, beds, buffets, bookcases entirely made in noble species cross generations as living heritage. Their manufacture requires demanding expertise: rigorous log selection, patient drying (several years for large thicknesses), traditional mortise and tenon joints, meticulous finishes. But result rewards this investment: incomparable physical presence, beauty enriching over years, natural time patina.

Solid wood lives, breathes, works according to ambient humidity. This characteristic, far from being defect, testifies to authentic organic nature. Solid oak tabletop slightly expands in humid summer, contracts in dry winter. Traditional cabinetmakers integrate these movements into their designs: joints allowing play, grooves and tongues, floating frames and panels. Exceptional solid wood repairability – sanding, refinishing, restoration – prolongs its life indefinitely.

Decisive advantages: Incomparable nobility and authenticity, transgenerational durability (100+ years), total repairability, magnificent patina with time, patrimonial value and transmission, unique beauty of each piece.

Considerations: Superior initial investment, natural wood movements to accept, necessary regular maintenance, significant weight, availability according to chosen species.

Veneer: Optimizing Rare Species

Veneering consists of cutting log into very thin sheets – 0.6 to 3 mm thickness – to cover stable support (plywood, MDF, particleboard). This millennial technique allows covering large surfaces with minimum quantity of precious wood, optimizing use of limited resources. One m³ walnut log would produce few solid furniture pieces, but hundreds of square meters of veneer. Economically and ecologically rational.

Veneer authorizes decorative effects impossible in solid wood. Traditional marquetry assembles hundreds of veneer pieces of varied species and colors in spectacular geometric or figurative compositions. Symmetries – “book-matched” veneers creating mirror patterns from same piece – exploit veinings to generate striking graphic effects. Burls – veneers from burls and knots – offer tormented textures of fascinating beauty, too fragile for solid use.

Significant advantages: Optimization of rare and precious species, dimensional stability superior to solid, unique decorative possibilities (marquetry, symmetries), lower cost than solid for same aesthetics, ecological (maximum material yield).

Limits to know: More delicate repairs than solid (delamination risk), edges to treat (solid or edge-banded), perceived as less noble than solid (unjustly), sensitive to impacts (possible lifting), requires quality support.

Molded Plywood: Modernist Revolution

Molded plywood literally revolutionized 20th century design by authorizing fluid organic forms impossible to achieve in solid wood. Principle: superimpose several thin wood sheets (plies) with fibers crossed at 90°, glue them under pressure in mold with desired curves. Once dry, panel definitively keeps its three-dimensional form. Alvar Aalto masterfully exploits this technique from the 1930s with his furniture with soft curves. Charles and Ray Eames bring it to its zenith with their iconic LCW and DCW chairs, fluid shells of stunning organic elegance.

Molded plywood advantages exceed mere formal aspect. Its crossed structure gives it remarkable mechanical resistance in all directions, unlike solid wood strong in grain direction but fragile perpendicular. Its lightness – exceptional strength/weight ratio – allows thin and airy structures. Its dimensional stability superior to solid avoids deformations. Edge aesthetics in “sandwich slices” revealing superimposed plies creates distinctive visual signature.

Emblematic applications: Chairs and seats with organic forms (Eames, Jacobsen, Panton), sculpted lighting fixtures (fluid curves), contemporary design furniture, curved architectural elements, formed partitions and cladding, skateboards and surfboards.

Technical characteristics: 3D forms impossible in solid, optimal lightness and resistance, excellent dimensional stability, industrial or artisanal production, distinctive modernist aesthetics, reasonable cost vs curved solid.

Derived Panels: Modern Technical Supports

Wood-derived panels – MDF (Medium Density Fiberboard), OSB (Oriented Strand Board), particleboard – constitute essential technical supports of contemporary furniture. Composed of wood fibers, particles or chips reconstituted and glued under pressure, they offer perfectly flat surfaces, dimensionally stable, available in large standardized dimensions, economically accessible. Their perfect flatness makes them ideal as veneer or lacquer supports.

MDF, finest and most homogeneous, perfectly accepts routings, moldings, lacquering. OSB, assumed raw aesthetics with large visible oriented chips, experiences success in contemporary design celebrating authentic industrial appearance. Particleboard, most economical, essentially serves as covered support (melamine, laminate, veneer). Crucial attention to glues: require formaldehyde E1 or better E0 (almost zero), as traditional glues emit harmful VOCs.

Practical advantages: Perfect flatness, total dimensional stability, large available dimensions, very accessible cost, machining ease, excellent veneer/lacquer support, wood waste valorization.

Necessary vigilance: Glue quality (prioritize E1/E0 low formaldehyde), limited moisture resistance (except waterproof versions), difficult repair (irreversible swelling if humidity), fragile edges (require protection), “low-end” perception if visible.

Cladding: Floors, Walls, Ceilings

Floors: Warmth and Nobility Underfoot

Flooring transforms simple floor into noble, warm, living surface. Three major technical families: solid flooring, boards entirely in noble wood, thick (10-23mm), nailed or glued, sanded and finished after installation – ultimate quality, 50-100 year lifespan, multiple renovation possible. Engineered flooring, sandwich structure with noble wood top layer (2.5-4mm) on plywood or HDF support, floating or glued installation, stability superior to solid, excellent quality-price ratio. Laminate, photographic imitation on particleboard support, is not true flooring but economical alternative.

Three installation types radically transform aesthetics of same species. Straight lay, parallel boards randomly staggered, remains most common and timeless. Herringbone, boards cut at 45-60° assembled in regular chevrons, brings sophistication and visual dynamism – associated with Parisian Haussmannian classicism. Versailles, complex geometric panels assembling small boards in patterns, evokes palatial opulence. Wide boards (180-220mm) create refined contemporary spaces; narrow boards (70-90mm) more traditional character.

Species choice by use: Heavy traffic (shops, halls) → oak, beech, maple (Brinell hardness above 30). Standard residential → oak, ash, cherry. Wet rooms → teak, bamboo, thermally treated wood. Light aesthetics → maple, bleached ash, light oak. Dark aesthetics → walnut, wenge (or stained alternatives).

Floor finishes: Sealed (varnish) = maximum protection, minimal maintenance, ideal traffic. Oiled = natural appearance, warm touch, easy local renovation. Waxed = soft patina, regular maintenance, light residential use.

Paneling and Wainscoting: Covering Walls and Ceilings

Paneling covers walls and ceilings with wood, instantly creating warm, muffled, intimate atmosphere. Historically developed to thermally and acoustically insulate cold castle rooms, it preserves these practical qualities today while bringing strong aesthetic dimension. Traditional tongue-and-groove paneling uniformly covers large surfaces. More elaborate wainscoting – moldings, frames, panels – architecturally structures walls creating rhythms and reliefs.

Varied styles according to eras and sought aesthetics. Rustic paneling in knotty pine or fir evokes mountain chalet, authentic country house. Paneling painted white or light gray, typical of Scandinavian interiors, brings brightness and refinement. Classical wainscoting with moldings and frames, oak or walnut, recreates elegance of Haussmannian apartments or English manors. Contemporary battens – regularly spaced wood slats – offer modern and airy graphics while playing with shadow and light.

Room by room applications: Bedrooms → warmth, soft acoustics, cocoon ambiance (pine, light oak). Living rooms → elegance, character (oak, walnut, wainscoting). Bathrooms → resistant species (teak, cedar) or thermally treated. Ceilings → often neglected dimension, spectacular effect (light paneling, battens).

Technical benefits: Complementary thermal insulation, acoustic absorption (reverberant rooms), wall defect masking, installation ease, reversible renovation, excellent durability.

Exterior Cladding: Protection and Aesthetics

Wood cladding radically transforms facade appearance while effectively protecting walls. True protective skin, it constitutes first line of defense against weather, UV, pollution. Its principle: ventilated framework creates air gap between wall and cladding, evacuating moisture, improving insulation, prolonging ensemble lifespan. Wood breathes, works, ages naturally – this evolution is integral part of its charm.

Two opposing aging philosophies. Let wood naturally gray under combined action of UV and humidity creates elegant silvery patina, uniform after 18-24 months exposure. Natural aesthetics, no maintenance, magnificently evolving appearance. Or apply stains/saturators to maintain original wood color, reinforced protection, periodic maintenance (every 3-5 years), constant controlled appearance. Both approaches defend depending on sought aesthetic result.

Recommended species: Douglas fir → pinkish color, correct durability, 100% French, economical. Larch → orange color, good durability, Alpine species. Red cedar → warm red, excellent but imported. Black locust → exceptional class 1 durability, local. Oak → prestige, durability, high cost. Thermally treated woods → performant alternatives.

Architectural trends: French contemporary architecture massively rediscovers wood cladding. Individual houses, collective buildings, public facilities celebrate wood on facades. Wood-metal, wood-concrete combinations create sophisticated graphic compositions. Vertical, horizontal or diagonal cladding visually structures volumes.

Structuring Architectural Elements

Exposed Frames: Expressive Structure

Exposed framing transforms structural necessity into major architectural element. Revealed beams, purlins, rafters affirm wood construction nobility, create rhythm and character, generate spectacular cathedral volumes. This millennial construction tradition experiences renewal in contemporary architecture celebrating structural honesty and authentic material beauty.

Traditional solid wood frames – mainly oak – assembled by mortise-tenons and wood pegs testify to exceptional artisanal expertise. Their generous sections, visible complex joints, centuries-old patina confer incomparable presence and authenticity. Contemporary frames exploit glued laminated timber allowing spectacular spans (30m and more) impossible in solid, audacious curved forms, precisely calculated optimized sections.

Styles and ambiances: Traditional oak frame = rustic authenticity, heritage. Glued laminated spruce frame = technical modernity, public spaces. Douglas/larch frame = contemporary mountain architecture. White/gray painted wood = refined Scandinavian style.

Stairs: Functional Sculpture

Wood staircase combines daily functionality and strong sculptural presence. Vertical structuring element, it organizes space, creates perspectives, captures gaze. Its design requires technical expertise – calculation of riser heights, tread depth, optimal slope – and aesthetic sensitivity – species choice, balustrade treatment, finishes. Beautiful staircase becomes interior architecture centerpiece.

Innumerable stylistic variations: traditional staircase with turned balusters evokes classical charm. Contemporary staircase with metal central stringer and floating wood treads creates spectacular airy lightness. Helical staircase sculpts space in elegant spiral. Closed or open risers, with or without nosing, full balustrades, with bars or glass, each detail contributes to ensemble character.

Species by use: Oak = solidity, durability, intensive use. Beech = hardness, economy. Walnut = prestige, beauty. Ash = contemporary clarity. Wood-metal mix = asserted modernity.

Ecological Dimension: Choosing Responsible Wood

Wood constitutes the only truly renewable, bio-sourced, carbon-storing construction and furnishing material. But this ecological evidence never dispenses with rigorous vigilance on provenance, certifications, transport impact, local alternatives. Non-certified tropical wood transported by plane from Asia loses all environmental benefit and participates in deforestation. FSC-certified French oak used locally conversely embodies ecological exemplarity.

Wood as Climate Solution

One cubic meter of dry wood stores approximately one ton of CO2 captured from atmosphere during tree growth. This carbon remains imprisoned in material for entire furniture, floor, frame lifespan – potentially centuries. A 5-story solid wood building thus stores equivalent of 3000 tons of CO2, active contribution to combating climate change. Provided of course that original forest is sustainably managed, i.e. systematically replanted.

French forest regularly progresses since 1850, gaining about 1% surface area per year. It today covers 31% of metropolitan territory versus 15% in 19th century. This progression testifies to globally sustainable management, even if improvements remain necessary concerning biodiversity and ancient forest preservation. Using FSC or PEFC certified French wood actively participates in this positive dynamic: demand stimulates responsible forest management, creates economic value that encourages forest maintenance and extension rather than conversion to agricultural land or urbanized zones.

French and European Woods: Unrecognized Wealth

French forest, third in Europe with 17 million hectares covering 31% of territory, offers remarkable species diversity largely underexploited. Pedunculate and sessile oak, beech, ash, cherry, chestnut, maple, hornbeam for hardwoods. Douglas fir, spruce, fir, Scots and maritime pine for softwoods. This richness allows meeting vast majority of wood needs without ever resorting to problematic tropical species.

Certain French regions produce internationally recognized woods of excellence. Tronçais oak (Allier), with slow growth and exceptional fine grain, supplies best barrels of world wine industry. Massif Central Douglas fir offers quality and considerable volumes. Slavonian oak (Croatia), although outside France, deserves mention as absolute European reference for grain and quality. Alpine resonance spruce, selected for unique acoustic qualities, has equipped most prestigious stringed instruments since Stradivarius.

French wood sector employs 400,000 people from silviculture to final transformation. Choosing certified French wood directly supports this local economy, preserves artisanal and industrial expertise, maintains rural vitality of forest regions. Traceability becomes possible: from forest parcel to finished product, less than 500 kilometers in many cases. This proximity drastically reduces transport carbon footprint while ensuring transparency and quality control.

Local Alternatives to Exotic Woods Table

| Exotic Wood | Origin | Issue | European Alternative | Treatment | Equivalence |

|---|---|---|---|---|---|

| TEAK | Southeast Asia | Massive deforestation | Black Locust | None (natural class 1) | Superior durability ✓✓✓✓ |

| Thermally Treated Oak | 200-230°C no oxygen | Good durability ✓✓✓ | |||

| Chestnut | None (natural tannins) | Natural class 2 ✓✓ | |||

| IPE | Brazil, Amazon | Deforestation | Black Locust | None | Comparable durability ✓✓✓✓ |

| Thermally Treated Oak | High temperature | Good for decks ✓✓✓ | |||

| WENGE | Central Africa | Overexploitation | Black-Stained Oak | Water-based stain | Similar aesthetics ✓✓ |

| Thermally Treated Ash | High temperature | Dark brown color ✓✓ | |||

| EBONY (CITES) | Madagascar, Africa | Near extinction | Black-Stained Pear | Black stain | Similar fine grain ✓✓✓ |

| Black Lacquered Wood | Opaque lacquer | Perfect color ✓✓ | |||

| ROSEWOOD (CITES) | South America, Asia | CITES Appendix II | European Walnut | None | Noble brown tones ✓✓✓ |

| Wild Cherry/Cherry | None | Warm tones ✓✓✓ | |||

| IROKO | Africa | Overexploitation | European Oak | None or thermally treated | Versatile, robust ✓✓✓✓ |

| Black Locust | None | Very durable exterior ✓✓✓ | |||

| MERBAU | Southeast Asia | Indonesian deforestation | Black Locust | None | Superior durability ✓✓✓✓ |

| MAHOGANY | America, Africa | CITES depending on species | Cherry | None | Similar red tones ✓✓✓ |

| European Walnut | None | Noble brown ✓✓ | |||

| DOUSSIE | Africa | Intensive exploitation | Thermally Treated Oak | High temperature | Comparable durability ✓✓✓ |

| Black Locust | None | Very durable exterior ✓✓✓ |

Equivalence legend: ✓✓✓✓ = Excellent or superior equivalence | ✓✓✓ = Very good equivalence | ✓✓ = Good viable equivalence | In 85% of cases, European alternative offers equivalent or superior performance with infinitely lower ecological impact.

Ecological Innovations in Wood

Modern wood modification technologies without toxic chemistry open remarkable perspectives. Thermal treatment, already mentioned, transforms common species into high-performance wood. Acetylation (Accoya process) modifies molecular structure with acetic anhydride – vinegar derivative, non-toxic – to create practically rot-proof and dimensionally ultra-stable wood. Oleothermy treats wood in hot vegetable oil bath, combining structural modification and natural protective impregnation.

CLT (Cross Laminated Timber) revolutionizes construction. These massive panels – up to 50cm thick – assemble several layers of boards crossed at 90°, glued under pressure. Exceptional structural resistance, load-bearing capacity allowing construction of 20+ story towers, excellent fire behavior (surface carbonization protects panel core), remarkable thermal and acoustic insulation, record assembly speed. Vienna, Vancouver, London, Paris see collective buildings entirely in CLT rising, spectacular demonstration of wood construction potential.

Circular economy valorizes wood at end of first life. Old beams from demolished frames, century-old deposited floors, decommissioned railway sleepers find second life in furniture, decoration, developments. This creative upcycling practice avoids waste, celebrates material patina and history, creates unique pieces loaded with memory. Sawmill waste – slabs, edgings, sawdust – transforms into particleboard, heating pellets, animal bedding, integral resource valorization.

Labels and Certifications: Critical Reading Guide

FSC (Forest Stewardship Council): the gold of wood labels. International certification created in 1993 by WWF and other environmental NGOs. Strict independent controls by accredited bodies. Three levels: FSC 100% (entirely certified wood), FSC Mixed (certified and controlled mixture), FSC Recycled. Rigorous environmental criteria: sustainable management, biodiversity preservation, respect for local populations’ rights. Complete supply chain traceability. International recognition by NGOs. Limit: high certification cost excludes small owners; some scandals revealed control flaws.

Learn more: Official FSC International Website

PEFC (Programme for the Endorsement of Forest Certification): European equivalent of FSC, more widespread in France. 8 million hectares PEFC certified in France (50% of private forest). Different approach: regional certification rather than exploitation by exploitation. Slightly less strict criteria than FSC according to some NGOs, but nevertheless serious. Advantage: lower cost, accessible to small forest owners. Regular controls by independent bodies. Growing recognition.

Learn more: PEFC International

Other relevant labels: Bois de France guarantees French origin without other specific environmental criteria. NF Environnement Ameublement certifies furniture on global ecological criteria (wood, glues, finishes). EU Ecolabel European equivalent. Natureplus German, very demanding on health and environment.

Labels to avoid (greenwashing): certifications created by producers themselves without external independent control. “Sustainable wood”, “Eco wood”, “Green certified” labels without internationally recognized certifying body. Vague “Managed forests” without criteria precision. When in doubt: verify on official FSC.org or PEFC.org sites. Absence of label = maximum risk, absolutely avoid for tropical woods.

Complementary resource: For in-depth comparison of different wood certifications and understanding their respective strengths and weaknesses, consult WWF Guide on Forest Certification.

Calculating Carbon Impact of Choices

Comparative carbon footprint for 1m³ of material (production + transformation):

- Local European certified wood: 100-150 kg CO2eq emitted – 900 kg stored = net balance -750 kg CO2 (carbon sink)

- Certified exotic wood with maritime transport: 400-600 kg CO2eq – 900 kg stored = net balance -300 to -500 kg CO2

- Non-certified exotic wood: 800-1200 kg CO2eq + unaccounted deforestation = ecological catastrophe

- Steel: 5000 kg CO2eq (no storage)

- Aluminum: 12000 kg CO2eq (environmental disaster)

- Concrete: 900 kg CO2eq (neutral at best)

Impact multiplying factors: Asia-Europe maritime transport: +250 kg CO2eq/m³. Air transport (exceptionally): +2000 kg CO2eq/m³. Non-sustainable exploitation contributing to deforestation: +500 to +2000 kg CO2eq + incalculable biodiversity destruction. Toxic chemical treatment: +50-100 kg CO2eq + soil and water pollution.

Simplified decision tool: 1) Systematically prioritize local FSC/PEFC certified wood = guaranteed minimal impact. 2) If exotic species seems essential: check equivalences table above, 90% of time alternative exists. 3) If truly no alternative: require FSC certified + CITES justification if necessary + verify traceability. 4) Integrate lifespan: better expensive durable wood than cheap wood frequently replaced. Over 50 years, French solid oak beats all competitors in global balance.

Responsible Purchase Checklist

- ☑ Verifiable FSC or PEFC certification (traceable number)

- ☑ Known and documented geographical origin

- ☑ Systematically prioritize France/Europe when available

- ☑ Avoid CITES except exceptional justification + valid permits

- ☑ Check local alternatives table before any exotic purchase

- ☑ Quality > price (long-term durability = real economy)

- ☑ Artisan/supplier transparent on traceability and committed to responsibility

- ☑ Ecological finishes (natural oils, low VOC water-based varnish)

- ☑ Repairability and transmission (solid wood > glued derivatives)

Wood, Future Material Anchored in History

Wood spans millennia without ever losing relevance or beauty. From Egyptian sarcophagi to contemporary CLT towers, from medieval solid oak chests to Eames molded plywood chairs, this living material accompanies humanity in its aesthetic and technical evolution. Its unique capacity to combine tradition and innovation, craftsmanship and industry, sensory warmth and structural performance explains its timelessness.

Knowing species, understanding finishes, mastering applications allows informed choices balancing beauty, functionality, durability, responsibility. Prioritizing certified local woods constitutes major ecological act: renewable material, carbon storage, local economy support, performant alternative to questionable tropical woods. French oak, ash, walnut, Douglas fir offer complete palette meeting vast majority of needs without compromising fragile tropical forests.

Investing in quality solid wood transcends simple furniture purchase. It means choosing permanence against planned obsolescence, repairability against disposable, generational transmission against ephemeral consumption. Well-designed solid oak furniture crosses centuries, develops noble patina, tells family stories, becomes living heritage. This long-term perspective justifies higher initial investment: over complete lifespan, noble wood becomes economically rational as much as ecologically virtuous.

The future of wood in design promises to be exciting. Technical innovations – thermal modification, acetylation, new composites – expand possibilities while remaining natural. Digital technologies – 3D modeling, CNC machining – authorize unprecedented forms. Urban wood architecture demonstrates construction potential. But fundamentally, what makes wood’s timeless strength remains unchanged: organic beauty, tactile warmth, nature connection, material authenticity. In world saturated with synthetic artifices, wood reaffirms elementary truth: nothing replaces living beauty of true natural material.

Touch wood. Feel grain under fingers, breathe characteristic scent of each species, observe unique veinings telling tree growth story. Choose with knowledge and conscience. Create with respect for material and environment. Wood, millennial material, remains material of the future.

Digital entrepreneur and craft artisan.

My work bridges craftsmanship, design history and contemporary creation, shaping a personal vision of luxury interior design.

Since 2012, I have been based in my workshop on the shores of Lake Annecy, creating bespoke interiors for architects, decorators and private clients.